Boxing, in the context of stretch ceilings, refers to the installation of a perimeter frame or structure around the ceiling area.

The boxing provides structural support and stability for the stretch ceiling material It helps to evenly distribute tension and weight across the ceiling surface, preventing sagging or distortion over time.

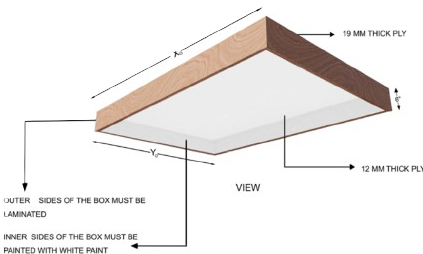

Boxing hides the edges of the stretch ceiling material, creating a clean and finished look. It conceals any imperfections or unevenness in the edges of the ceiling, enhancing the overall aesthetic appeal.

Boxing allows for the integration of lighting fixtures, ventilation systems, speakers, or other ceiling-mounted accessories. These elements can be recessed into the boxing, maintaining a seamless appearance while providing functional benefits.

Installing a boxing frame simplifies the installation process for stretch ceilings. It provides a clear boundary for stretching and securing the ceiling material, ensuring a smooth and professional finish.

We offer proprietary aluminium profiles for producing light box shapes. Our in-house bending system with advanced CNC machines enables these complex designs showcasing our unique capabilities.